In the intricate world of casting, chills play a pivotal role in ensuring the quality and integrity of the final product. This guide will delve into the definition, purpose, materials, and rules associated with chills in casting, offering a comprehensive understanding for professionals in the field. Additionally, we will demonstrate the usage of chills and their effect on thermal heat transfer using Z-Cast, a casting simulation software.

Introduction to Chills

Chills are instrumental in influencing the quality and yield of a casting. By strategically using chills, one can achieve a specific microstructure, reduce energy consumption, and enhance the overall efficiency of the casting process. Historically, the application of chills was based on experience, but modern advancements allow for precise calculations and simulations to optimize their use.

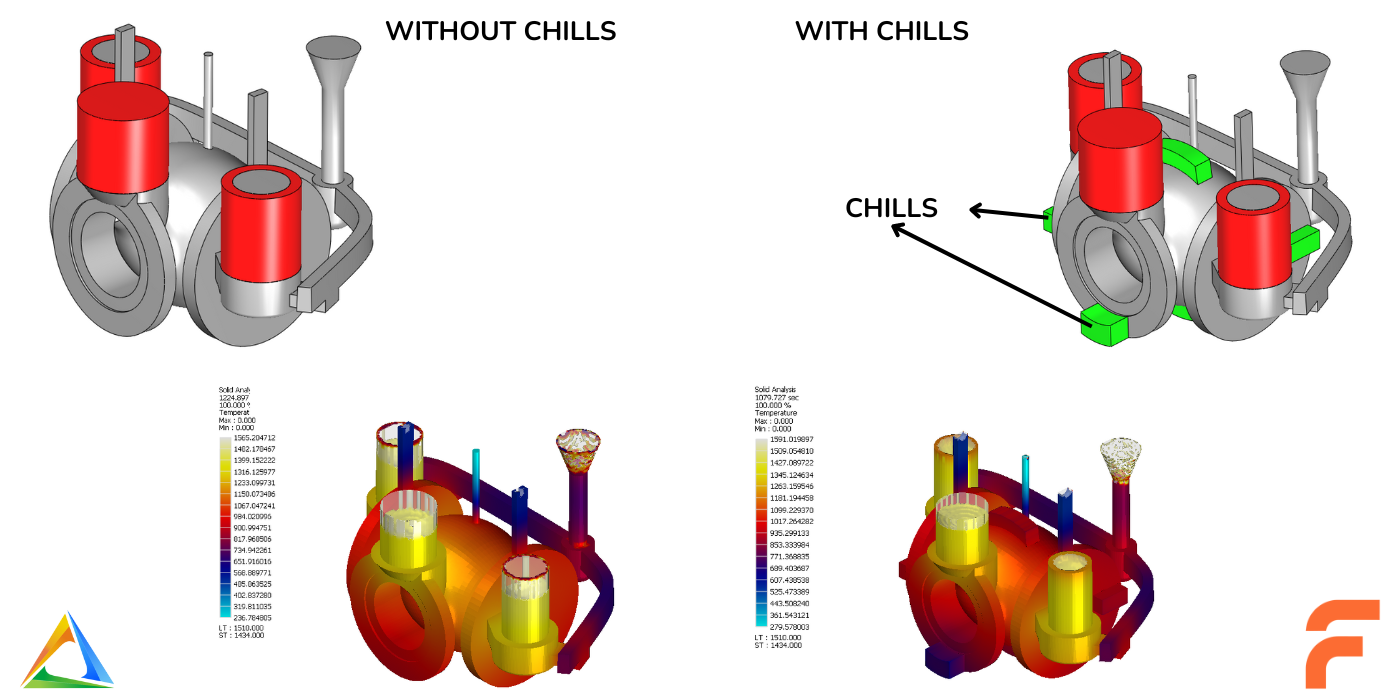

Demonstration with Z-Cast

Using Z-Cast, a casting simulation software, we can visualize the effects of chills on thermal heat transfer. As seen in the simulation images, there is a significant drop in temperature in areas where the chill is in contact with the casting. This sudden drop is crucial for promoting the desired cooling rates and achieving optimal solidification patterns.

What are Chills?

A chill is any material used to reduce the temperature of a specific area within a casting. This is achieved through materials with high specific heat and heat conductivity. Chills can be made from various substances, including special sands like chromite and zircon, metals such as grey iron, and even graphite. Importantly, chills must have a melting point significantly higher than the casting metal to prevent melting during the process.

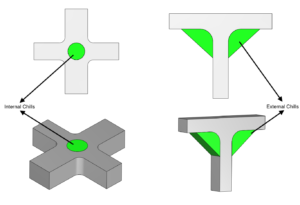

There are two main types of chills:

- External Chills: Placed on the surface of the casting.

- Internal Chills: Incorporated inside the casting and become part of the final product.

The Purpose of Using Chills

Chills serve several crucial functions in the casting process:

- Heat Removal: They locally remove extra heat, leading to a lower modulus in the affected section.

- Directional Solidification: Chills help promote directional solidification, increasing the feeding length of risers.

- Microstructure Control: They can induce a finer grain structure, enhance strength and ductility, increase hardness and hardenability, reduce porosity, and improve pressure tightness.

- Prevent Hot Cracks: By managing the cooling rate, chills can prevent hot cracks in critical areas.

Materials for Chills

The efficiency of chills is heavily influenced by the material used. The primary materials include:

- Iron: Various types of iron can be used, with grey iron (containing lamellar graphite) being the most effective due to its high heat conductivity.

- Special Sands: Materials like chromite, zircon, and magnesite sands are used for their specific thermal properties.

- Graphite: Offers high cooling efficiency and excellent surface condition, making it ideal for core applications.

- Other Materials: Silico-carbide and mullite-based materials, known for their thermal stability and low expansion, are also used.

Rules for Using Chills

To maximize the effectiveness of chills, certain rules and calculations must be followed:

- Calculation of Chill Volume: The volume of the chill should be calculated based on the required cooling effect and the specific heat properties of the chill material.

- Placement and Contact: The contact surface area between the chill and the casting should be optimized to ensure efficient heat transfer.

- Temperature Considerations: Preheating chills to avoid moisture and optimizing the temperature difference between the chill and the casting metal are critical for effective chilling.

Conclusion

Chills are an essential component in the casting process, offering numerous benefits from improved microstructure to enhanced casting quality. By understanding the types, purposes, materials, and rules associated with chills, casting professionals can significantly improve their processes, leading to higher quality and more efficient productions. This guide provides a foundational understanding, and integrating this knowledge with practical experience and advanced simulations will yield the best results in casting applications.