The Basic Principle of Ultrasound in Testing

Ultrasonic Testing (UT) leverages the basic principle of ultrasound to inspect materials and detect flaws without causing damage. By using high-frequency sound waves, UT examines how these waves interact with materials to identify any discontinuities. Understanding this principle is crucial for effective non-destructive testing and ensuring material integrity.

Wave Propagation in Ultrasonic Testing

Sound waves propagate through materials by the vibration of particles within the material. These vibrations, referred to as acoustics, occur when particles move in harmony to produce mechanical waves. There are four principal modes of wave propagation in solids:

- Longitudinal Waves: These waves cause particles to oscillate in the direction of wave propagation, creating compressions and expansions. They can travel through solids, liquids, and gases.

- Shear Waves: Particles oscillate perpendicular to the direction of wave propagation. Shear waves require a solid medium and are typically weaker than longitudinal waves.

- Surface Waves (Rayleigh Waves): These waves travel along the surface of a solid and penetrate to a depth of one wavelength. They combine both longitudinal and shear wave motions, making them sensitive to surface defects.

- Plate Waves (Lamb Waves): These waves propagate in thin materials and involve complex vibrations parallel to the surface. They are useful for inspecting large, thin structures like plates and tubes.

Key Properties of Acoustic Waves

Three critical properties of acoustic waves in ultrasonic testing are wavelength, frequency, and velocity:

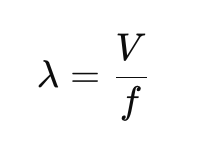

- Wavelength (λ): The distance between successive peaks of the wave. It is directly proportional to the velocity (V) and inversely proportional to the frequency (f) of the wave.

- Frequency (f): The number of oscillations per second, measured in Hertz (Hz).

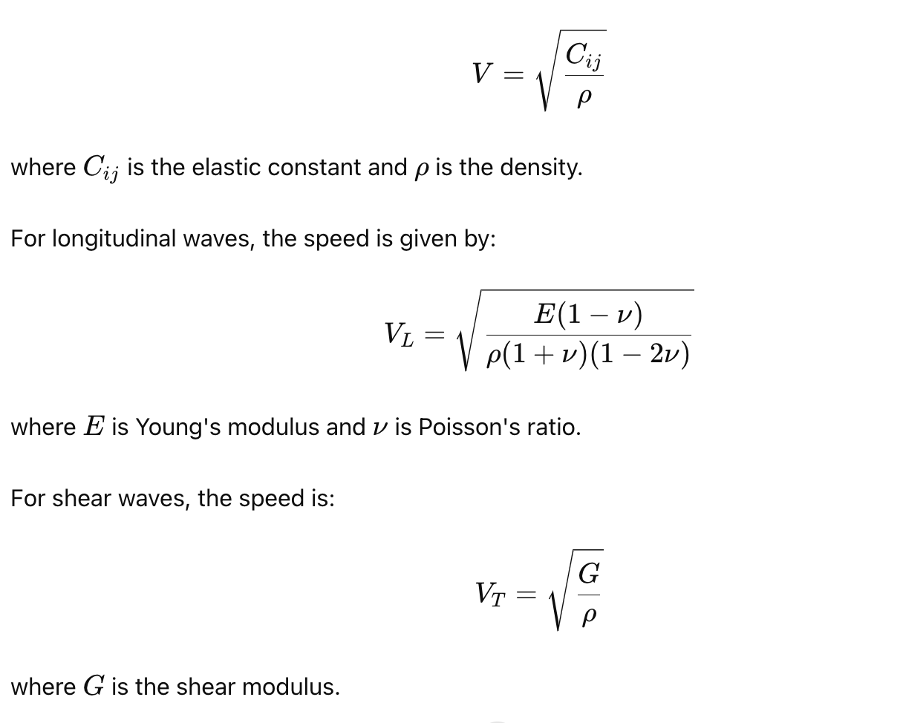

- Velocity (V): The speed at which sound waves travel through a medium, determined by the medium’s density and elastic constants.

For example, the velocity of longitudinal waves in steel is about 5850 m/s. The wavelength of these waves can be calculated based on the frequency used during testing.

The Role of Material Properties

The speed of sound in a material is influenced by its density and elastic properties. Hooke’s Law and Newton’s Second Law explain the relationship between the displacement of particles and the forces acting on them. The general formula for the speed of sound in a solid material is:

Attenuation and Defect Detection

Attenuation and Defect Detection

As sound waves travel through a material, their intensity diminishes due to spreading, scattering, and absorption. This attenuation affects the ability to detect flaws, especially those smaller than the wavelength of the sound. Higher frequencies offer better sensitivity and resolution but reduce penetration depth due to increased scattering.

In conclusion, the effectiveness of Ultrasonic Testing relies on a deep understanding of wave propagation, material properties, and the physics of sound. By leveraging these principles, UT can provide precise and reliable inspections of critical materials and components.