Introduction

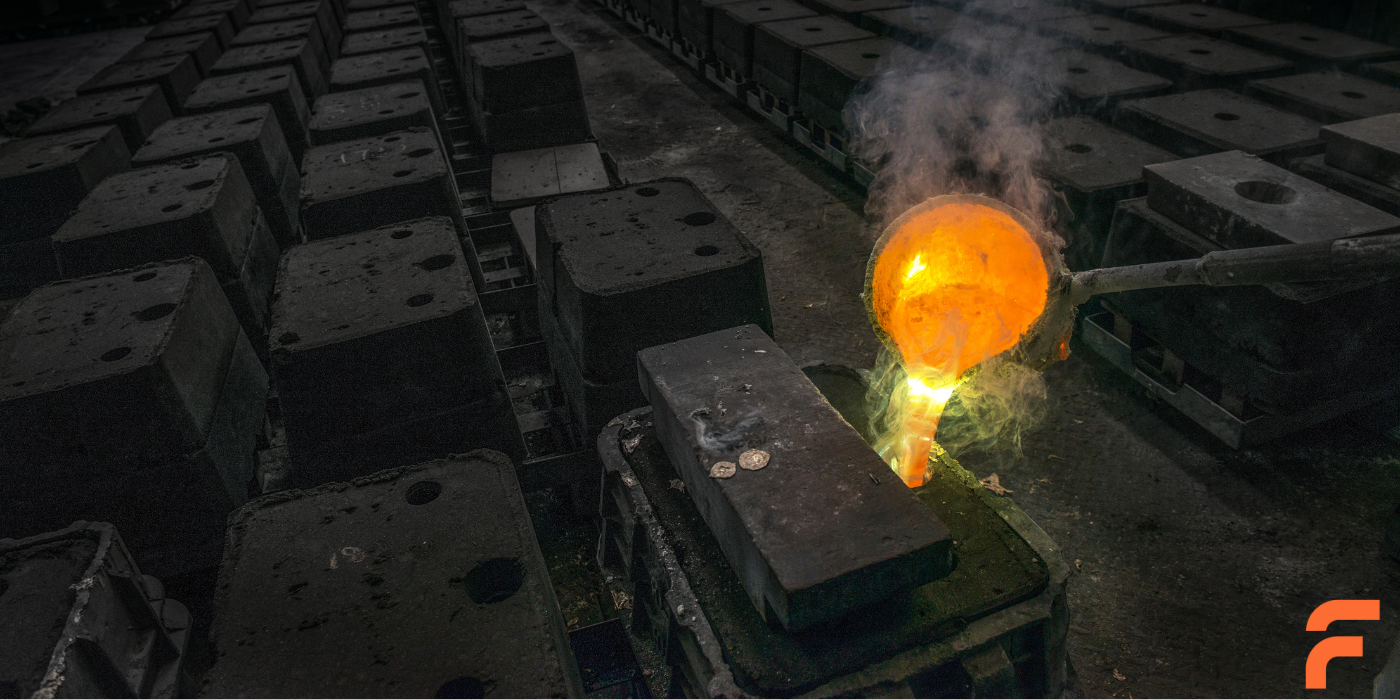

In the ever-evolving foundry industry, the Cold Box Process has emerged as a significant innovation over the past decade. This process, which allows for the curing of cores at room temperature within a cycle time, has considerably improved the core-making process. Invented by Dr. Jains Robins and patented on November 5, 1968, the Cold Box Process was formally introduced to the foundry industry at the A.F.S Congress and Exposition in 1968. This blog delves into the Cold Box Process, its components, equipment, and safety measures, highlighting its impact on the foundry industry.

What is the Cold Box Process?

The Cold Box Process is a three-part organic-based binder system, consisting of:

- Resin Part I: A phenol-formaldehyde polymeric condensate dissolved in a blend of aliphatic and aromatic solvents.

- Hardener Part II: A cross-linking agent containing polymeric MDI (Methylene Diphenyl Diisocyanate) blended with similar solvents.

- Catalyst Part III: TEA (Triethylamine) or MDEA (Dimethylethylamine), which are liquid tertiary amines.

In this process, the resin and hardener mix to form a solid urethane resin in the presence of the amine catalyst, bonding the sand grains together. This process offers several advantages, including producing strong cores, excellent dimensional accuracy, exceptional collapsibility, and low gas content. Additionally, it significantly enhances productivity, being four times faster than the shell process, and is suitable for all types of metals like steel, grey and ductile iron, aluminum, and magnesium.

Plant and Equipment

Sand Mixers

Sand mixers play a crucial role in the Cold Box Process. They ensure that the sand is mixed efficiently to achieve higher tensile strengths. There are two main types of mixers:

- Batch Mixers: These include blade and wheel-type mullers, known for their efficiency.

- Continuous Mixers: These mixers are preferred for their ability to mix sand rapidly and only in the required quantity, minimizing heat buildup and ensuring optimal sand consumption within its bench life.

Gas Generators

Gas generators are used to introduce the catalyst into the sand mixture. There are two types:

- Injector Type: This type forces liquid amine into a stream of fast-moving carrier gas, evaporating the amine and transporting it into the core box.

- Bubbler Type: This type gasifies the amine by bubbling the carrier gas through a deep batch of liquid amine.

Compressed Air Dryers

Compressed air is essential for the gas generator, core blowers, and pneumatic sand conveyors. Any moisture in the compressed air can adversely affect the final core strength and storage life. Two types of compressed air dryers are commonly used:

- Chemical Dryers: These are preferred for their effectiveness, achieving a dew point of -40°C.

- Refrigeration Dryers: These achieve a dew point of 0 to +4°C but are less effective compared to chemical dryers.

Safety and Hygiene in the Cold Box Process

Safety and hygiene are paramount in the Cold Box Process due to the use of potentially hazardous materials.

Part I Resin

Part I resin is a phenol-formaldehyde resin in a mixture of organic solvents. It is highly irritating to the skin and eyes, and protective clothing is required. Vapors can also be irritating, so adequate ventilation is necessary to maintain safe levels of airborne contaminants.

Part II Hardener

The hardener is a blend of polymeric isocyanate in organic solvents. While the polymeric isocyanates have low vapor pressures, the solvents can be irritating. Similar handling precautions as with Part I are required, including proper ventilation.

Part III Catalyst

The catalyst, usually TEA or MDEA, is a flammable alkaline liquid with a strong odor. It should be stored in designated areas due to its low flash point and potential health hazards. Proper ventilation is crucial, and contact with skin and eyes should be avoided.

Conclusion

The Cold Box Process has revolutionized core making in the foundry industry, offering numerous benefits such as improved core quality, increased productivity, and energy savings. By understanding and implementing the proper procedures, equipment, and safety measures, foundries can leverage this innovative process to enhance their operations and produce high-quality castings efficiently. The continued advancement and adoption of the Cold Box Process signal a promising future for the foundry industry.