Introduction to Welding

Welding is a fundamental skill in various industries, crucial for constructing and repairing metal structures. It involves joining materials, usually metals, by melting and fusing them. The welding techniques and applications are diverse, catering to different requirements and environments.

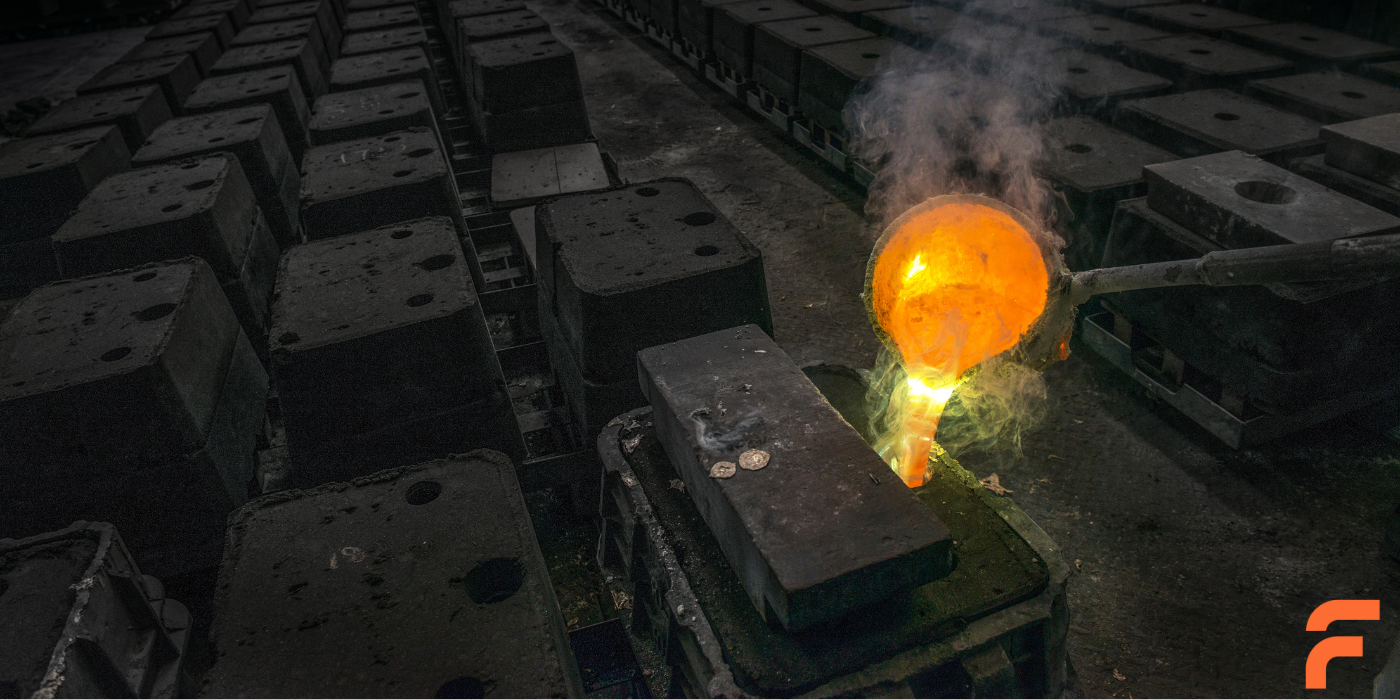

Safety First: Precautions in Welding

Safety is paramount in welding due to the potential hazards like intense light, heat, and toxic fumes. Proper protective gear, including welding helmets, gloves, and protective clothing, is essential. Specific precautions vary with different welding methods:

- Oxyfuel Welding: Be cautious of gas leaks and proper flame adjustment.

- Arc Welding and Cutting: Ensure good ventilation to avoid inhaling fumes.

- Gas Shielded Arc Welding: Maintain gas flow to protect the weld area from contamination.

- Welding Containers and Polyurethane Foam: Special precautions are needed for welding containers that held combustibles and foam-filled assemblies to prevent explosions.

Understanding Welding Symbols and Print Reading

Reading welding blueprints and symbols accurately is crucial for executing proper welds. Symbols provide detailed information on the type, size, and length of welds, while blueprints guide the overall welding plan.

Equipment Essentials

Welding requires various equipment, tailored to specific techniques:

- Oxyacetylene Equipment: Used for welding and cutting with acetylene gas.

- Arc Welding Equipment: Includes machines for both alternating current (AC) and direct current (DC) welding.

- Resistance Welding Tools: Used for spot and seam welding.

- Specialized Equipment: Such as thermit and forge welding tools.

Types of Welding Techniques and Welds

Mastering different welding techniques and understanding the types of welds are key to successful welding:

- Welding Positions: Practice in different positions like flat, horizontal, vertical, and overhead is necessary.

- Weld Types: Includes fillet welds, groove welds, and surface welds.

Identifying and Working with Metals

Knowledge of metal characteristics and their weldability is crucial. Metals are categorized as ferrous (iron-based) or nonferrous (not iron-based), each with distinct properties affecting the welding process.

Electrodes and Filler Metals

The choice of electrodes and filler metals significantly impacts weld quality. Different types of electrodes are used based on the metal being welded and the welding method.

Maintaining Welding Equipment

Regular maintenance of welding equipment ensures safety and efficiency. This includes checking for gas leaks, ensuring electrical connections are secure, and keeping the equipment clean.

Advanced Welding and Cutting Processes

Advanced techniques, such as underwater welding, metallizing, and flame cutting, expand the scope of welding applications. These specialized processes require additional skills and safety measures.

Destructive and Non-Destructive Testing

Testing welded joints is essential to ensure their integrity and strength. Destructive tests physically break the weld to examine its properties, while non-destructive tests use methods like X-rays to inspect the weld without damaging it.

Conclusion

Welding is a complex but rewarding skill, combining science and art. By understanding the theory, practicing techniques, and adhering to safety protocols, one can master the craft of welding, contributing to the creation of robust and reliable metal structures.