What is Corrosion?

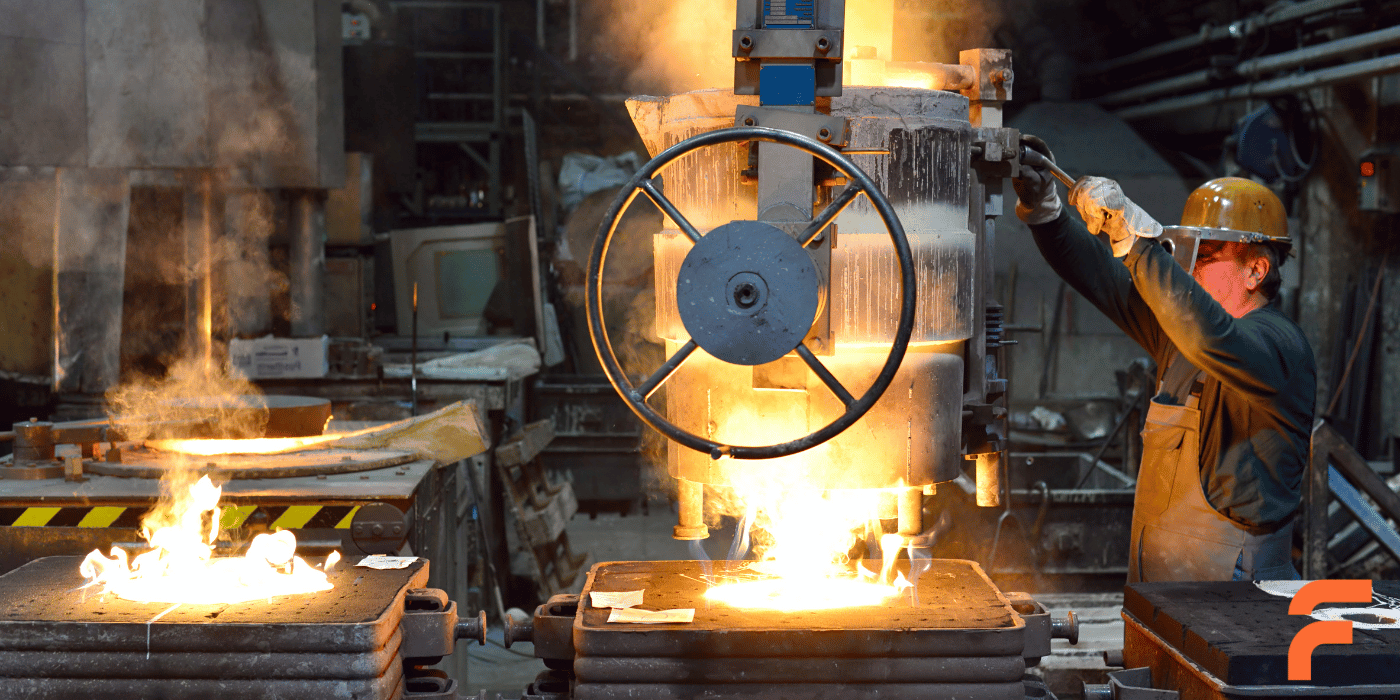

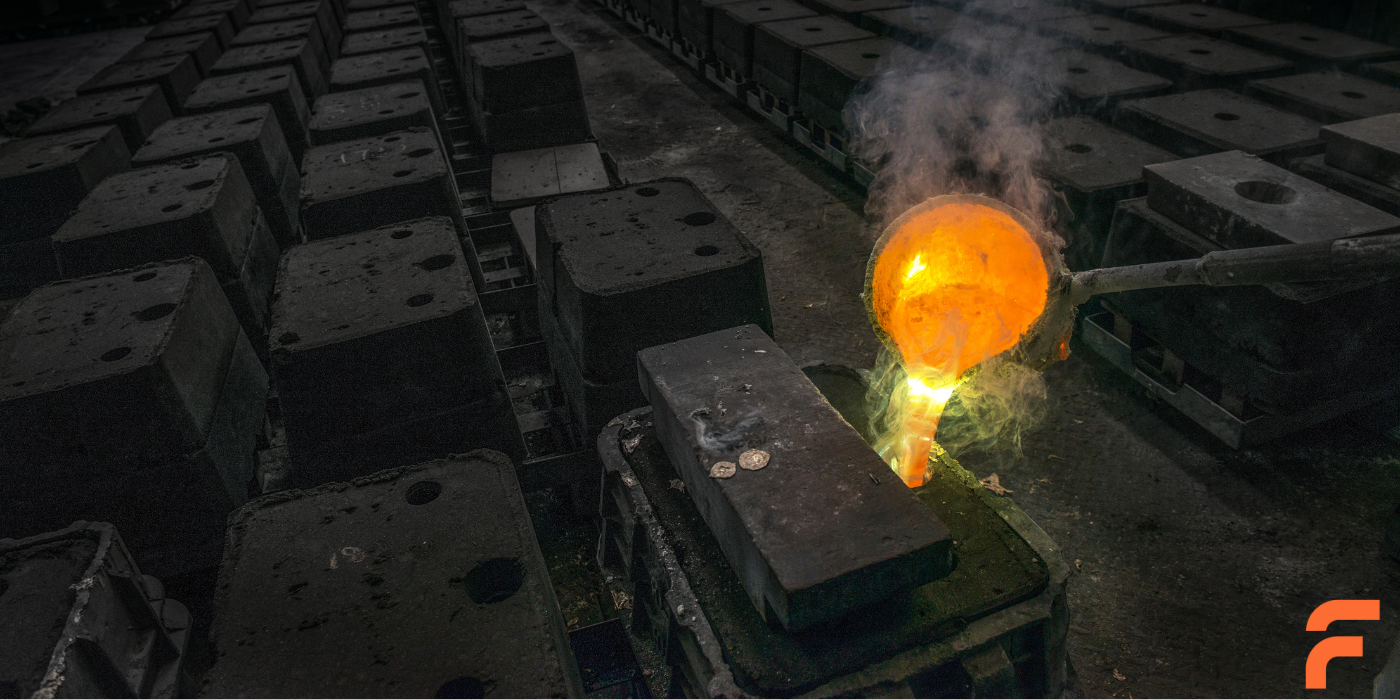

Corrosion is the gradual destruction of materials, typically metals, through chemical reactions with their environment. This process can also affect non-metallic materials like plastics, concrete, and wood, but it is most commonly associated with metals, particularly iron and steel.

Consequences of Corrosion

The impact of corrosion extends far beyond the mere loss of metal. Some of the significant consequences include:

- Structural Weakness and Failure: Loss of metal thickness can lead to mechanical failure. Localized corrosion can cause severe weakening even with minimal metal loss.

- Safety Hazards: Structural failures due to corrosion can result in injuries or fatalities, particularly in bridges, cars, and aircraft.

- Economic Losses: Corrosion can lead to expensive replacements and downtime in industrial equipment.

- Product Degradation: Corrosion can contaminate products, such as making beer cloudy due to released heavy metals.

- Environmental Damage: Leaks caused by corrosion can damage the surroundings, like a leaky radiator damaging household items or seawater entering power station boilers.

- Loss of Surface Properties: Corrosion can degrade important surface characteristics such as frictional properties, electrical conductivity, and heat transfer efficiency.

- Mechanical and Blockage Issues: Corrosion products can damage valves, pumps, and block pipes.

- Increased Design Complexity: Equipment must be designed to handle corrosion, adding complexity and cost.

Chemistry of Corrosion

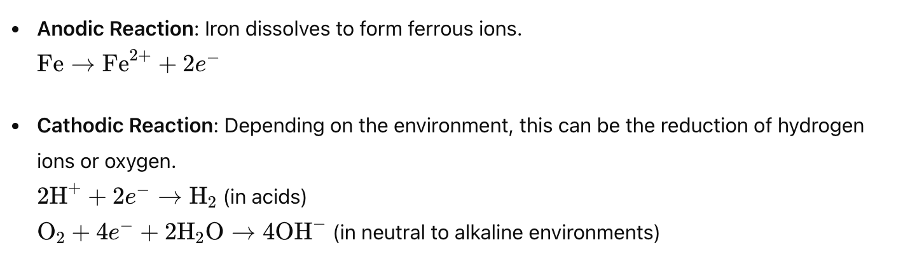

Corrosion is primarily an electrochemical process where metals revert to their natural, more stable states by releasing energy. This process involves anodic reactions, where metals dissolve into ions, and cathodic reactions, where these ions react with components in the environment. For instance, in iron corrosion:

Factors Influencing Corrosion Rate

Several factors can accelerate corrosion, including:

- Localized Cell Action: Metals with different electrochemical properties in contact can create galvanic couples, concentrating corrosion in small areas.

- Aggressive Ions: Ions like chlorides and sulfates can increase corrosion by preventing protective oxide film formation.

- Environmental Conditions: pH levels, oxygen content, flow rate, and the presence of other ions in the water can significantly impact corrosion rates.

Corrosion Prevention/Control Methods

There are several strategies to control and prevent corrosion:

- Metal Conditioning:

- Coatings: Applying protective coatings such as paint, galvanizing with zinc, or anodizing aluminum.

- Alloying: Creating corrosion-resistant alloys like stainless steel.

- Environmental Conditioning:

- Removing Oxygen: Using reducing agents like sulfite to remove oxygen in closed systems.

- Corrosion Inhibitors: Adding chemicals that reduce the rate of corrosion by interfering with the anodic or cathodic reactions.

- Electrochemical Control:

- Cathodic Protection: Applying a cathodic current to the metal to prevent anodic reactions.

- Anodic Protection: In specific environments, applying an anodic current to form a protective oxide film on the metal.

Conclusion

Corrosion is a complex, multifaceted issue that can have significant economic, safety, and environmental impacts. Understanding its underlying chemistry and factors can help in developing effective prevention and control strategies. By employing methods such as coatings, alloying, environmental conditioning, and electrochemical control, the detrimental effects of corrosion can be mitigated, ensuring the longevity and reliability of metal structures and components.